How PalletMach Pioneered Cable Skins Molded Pallets from Unrecyclable Waste

Late at night, in a factory in Japan, piles of black cable skins lay heaped like small mountains, releasing a strong and pungent odor. Once considered "completely unrecyclable," this industrial waste was destined for landfills—until now. Thanks to a breakthrough project by PalletMach, these discarded cable skins are being reborn as high-performance cable skins molded pallets!

This initiative is not only the first in the industry to successfully mass-produce eco-friendly cable skins molded pallets using complex cable skins, but it also represents a true technical revolution—turning stubborn waste into valuable, functional products.

I. A "Near-Impossible" Challenge from Across the Ocean

In July 2023, PalletMach received an inquiry from Japan. A client there had accumulated large volumes of waste cable skins (primarily made of PVC and rubber) and wanted to transform them into strong, durable cable skins molded pallets.

Due to the material's complexity, no local supplier would take on the project.

After discovering PalletMach's expertise in plastic recycling, the client reached out—hopeful yet skeptical.

Cracking the "Unrecyclable" Material

Confronted with this tough challenge, PalletMach formed a dedicated task force. Initial analysis confirmed that using 100% cable skins would not produce cable skins molded pallets with sufficient strength or consistency.

The team devised an innovative solution: by blending rice husks—a low-cost, locally available natural material—into the cable skins, they enhanced both the performance and sustainability of the final cable skins molded pallets.

The client welcomed this creative and cost-effective approach.

II. Engineering a Highly Automated "Factory of the Future"

Aware of Japan's high labor costs and aging workforce, the client emphasized the need for full automation. PalletMach delivered a smart, nearly turnkey solution:

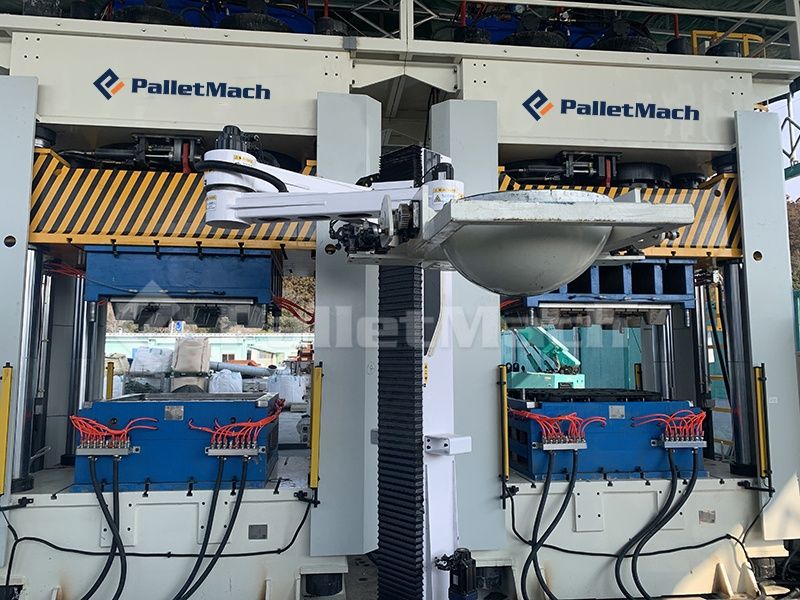

Core Machinery

Two fully automatic compression molding machines for cable skins molded pallets, two chillers, and two sets of custom molds.

(Front view of the plastic pallet machine)

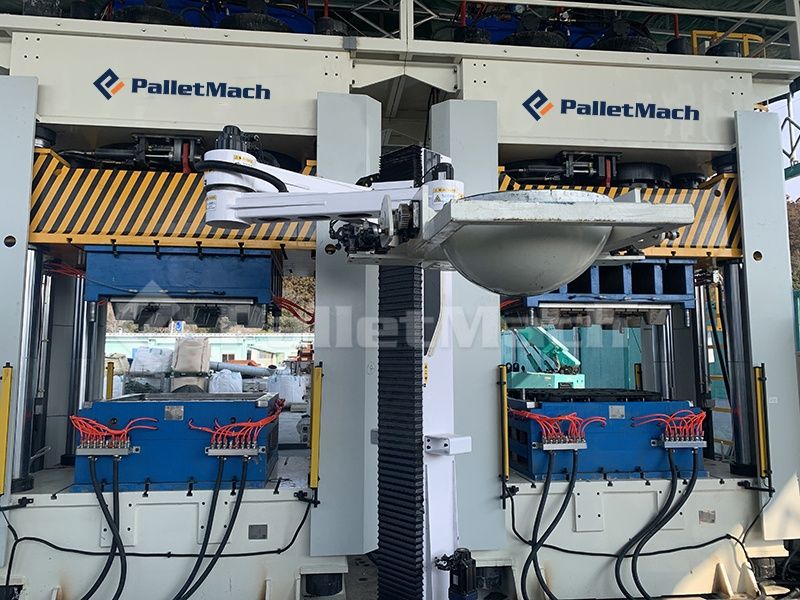

Automated Handling

Two robotic arms equipped with a custom "scoop-type" Feeder designed specifically for handling cable skins and placing finished cable skins on molded pallets with precision.

(robotic arm)

Integrated Production Line

A seamless system including high-precision weighing, automated conveyors, and smart palletizing, all optimized for handling cable skins and producing uniform cable skins molded pallets.

(The back of the production line)

Process Innovation

An upgraded feeding and plasticizing system ensures accurate material dosing—superior to conventional injection—resulting in consistent weight and quality across all cable skins molded pallets.

III. On-the-Ground Innovation: From Blueprint to Reality

PalletMach's engineers traveled to Japan for installation and commissioning.

They adjusted the process in real-time to accommodate variations in the cable skins, reconfigured equipment layout to fit the plant, and tackled every challenge hands-on.

Their expertise ensured a smooth launch for this one-of-a-kind production line.

Outstanding Results: High-Performance cable skins molded pallets

After 14 months of dedicated effort, what was once waste material is now a high-value product. Using high-pressure molding technology, PalletMach has transformed cable skins into premium cable skins molded pallets with:

(Finished pallet display)

✅ Superior Quality

Smooth, burr-free surfaces and consistent dimensions. Excellent resistance to moisture and corrosion.

✅ Exceptional Strength

Static load capacity up to 6 tons; dynamic load reaches 1.5 tons. Customizable designs can increase the dynamic load to 2 tons.

✅ Smart & Safe Design

Reinforced ribs scientifically integrated into the mold enhance structural strength. Uniform sizing enables stable stacking. Multiple anti-slip patterns available.

✅ Eco-Friendly & Economical

99% material utilization with near-zero waste. Significant reduction in raw material cost compared to traditional injection molding.

No matter how challenging your plastic waste—especially hard-to-recycle materials like cable skins—PalletMach can help you transform it into high-value cable skins molded pallets. Together, we can achieve both sustainability and profit.

This initiative is not only the first in the industry to successfully mass-produce eco-friendly cable skins molded pallets using complex cable skins, but it also represents a true technical revolution—turning stubborn waste into valuable, functional products.

I. A "Near-Impossible" Challenge from Across the Ocean

In July 2023, PalletMach received an inquiry from Japan. A client there had accumulated large volumes of waste cable skins (primarily made of PVC and rubber) and wanted to transform them into strong, durable cable skins molded pallets.

Due to the material's complexity, no local supplier would take on the project.

After discovering PalletMach's expertise in plastic recycling, the client reached out—hopeful yet skeptical.

Cracking the "Unrecyclable" Material

Confronted with this tough challenge, PalletMach formed a dedicated task force. Initial analysis confirmed that using 100% cable skins would not produce cable skins molded pallets with sufficient strength or consistency.

The team devised an innovative solution: by blending rice husks—a low-cost, locally available natural material—into the cable skins, they enhanced both the performance and sustainability of the final cable skins molded pallets.

The client welcomed this creative and cost-effective approach.

II. Engineering a Highly Automated "Factory of the Future"

Aware of Japan's high labor costs and aging workforce, the client emphasized the need for full automation. PalletMach delivered a smart, nearly turnkey solution:

Core Machinery

Two fully automatic compression molding machines for cable skins molded pallets, two chillers, and two sets of custom molds.

(Front view of the plastic pallet machine)

Automated Handling

Two robotic arms equipped with a custom "scoop-type" Feeder designed specifically for handling cable skins and placing finished cable skins on molded pallets with precision.

(robotic arm)

Integrated Production Line

A seamless system including high-precision weighing, automated conveyors, and smart palletizing, all optimized for handling cable skins and producing uniform cable skins molded pallets.

(The back of the production line)

Process Innovation

An upgraded feeding and plasticizing system ensures accurate material dosing—superior to conventional injection—resulting in consistent weight and quality across all cable skins molded pallets.

III. On-the-Ground Innovation: From Blueprint to Reality

PalletMach's engineers traveled to Japan for installation and commissioning.

They adjusted the process in real-time to accommodate variations in the cable skins, reconfigured equipment layout to fit the plant, and tackled every challenge hands-on.

Their expertise ensured a smooth launch for this one-of-a-kind production line.

Outstanding Results: High-Performance cable skins molded pallets

After 14 months of dedicated effort, what was once waste material is now a high-value product. Using high-pressure molding technology, PalletMach has transformed cable skins into premium cable skins molded pallets with:

(Finished pallet display)

✅ Superior Quality

Smooth, burr-free surfaces and consistent dimensions. Excellent resistance to moisture and corrosion.

✅ Exceptional Strength

Static load capacity up to 6 tons; dynamic load reaches 1.5 tons. Customizable designs can increase the dynamic load to 2 tons.

✅ Smart & Safe Design

Reinforced ribs scientifically integrated into the mold enhance structural strength. Uniform sizing enables stable stacking. Multiple anti-slip patterns available.

✅ Eco-Friendly & Economical

99% material utilization with near-zero waste. Significant reduction in raw material cost compared to traditional injection molding.

No matter how challenging your plastic waste—especially hard-to-recycle materials like cable skins—PalletMach can help you transform it into high-value cable skins molded pallets. Together, we can achieve both sustainability and profit.