PalletMach Waste Plastic Recycling Solution has Created Green Pallets

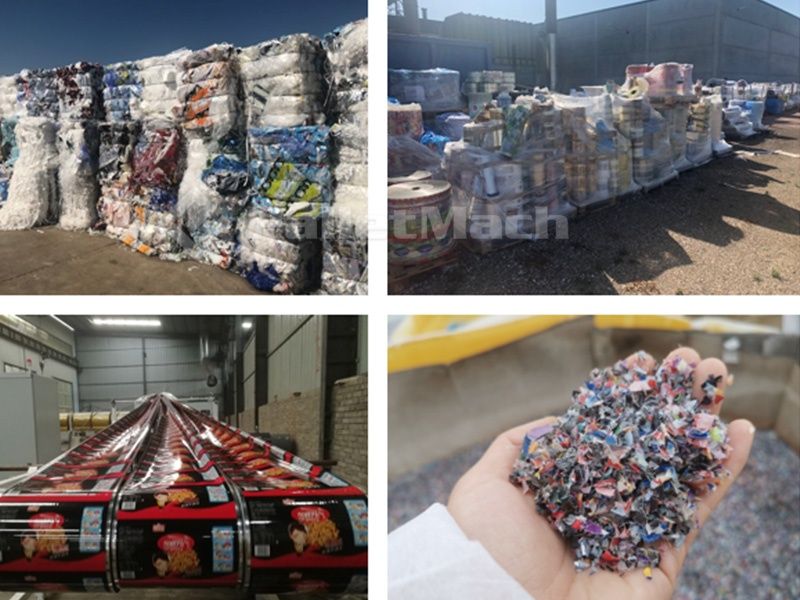

Mountains of mixed waste plastics worldwide are eroding land and polluting the air. From TV casings in Chile, agricultural mulch films in Xinjiang, to food bags in Iran and composite waste plastics in Japan... These "non-recyclable" pollution sources are reborn as 10,000-ton high-strength pallets through PalletMach's innovative Waste Plastic Recycling Solution.

Global Waste Plastics Transformed via PalletMach's Waste Plastic Recycling Solution

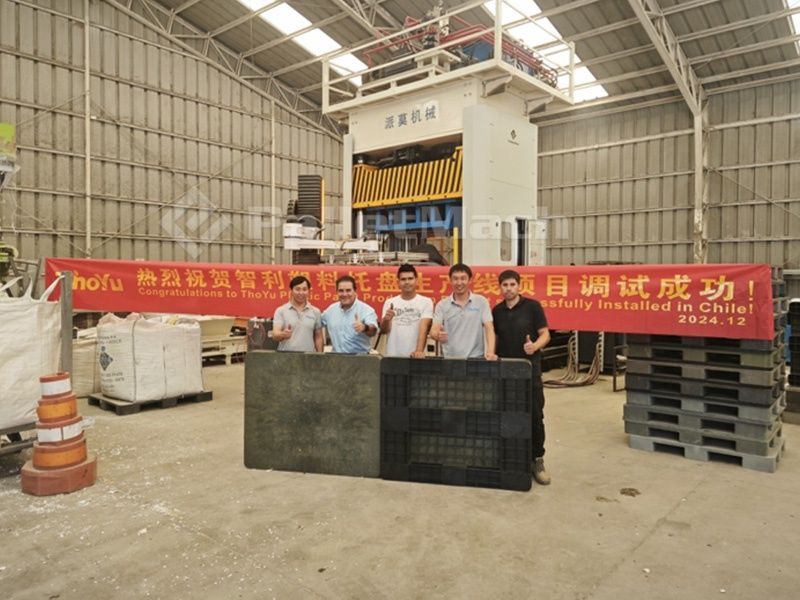

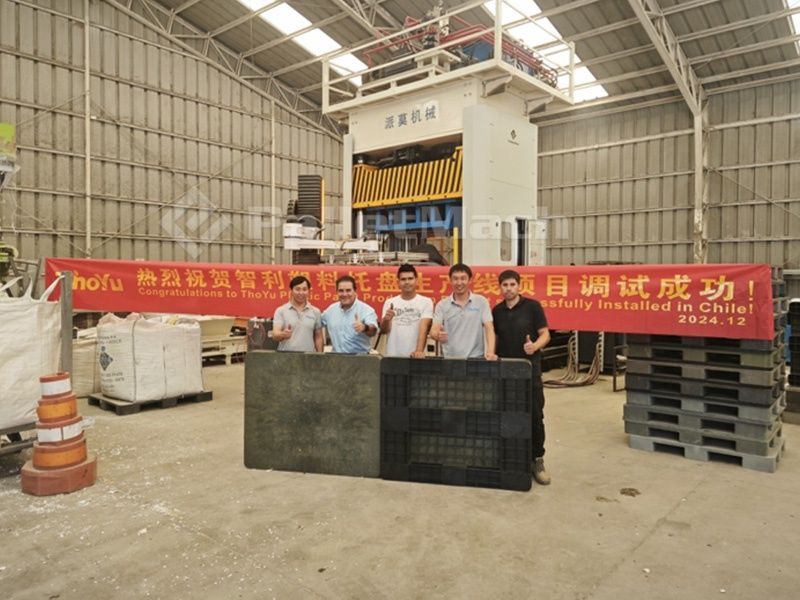

Chile

Customer's raw materials: Polyethylene sheets, crushed TV materials, and large bag materials (mainly polypropylene).

Through PalletMach's tailored Waste Plastic Recycling Solution, engineers achieved successful debugging, with high-quality pallet samples delivered.

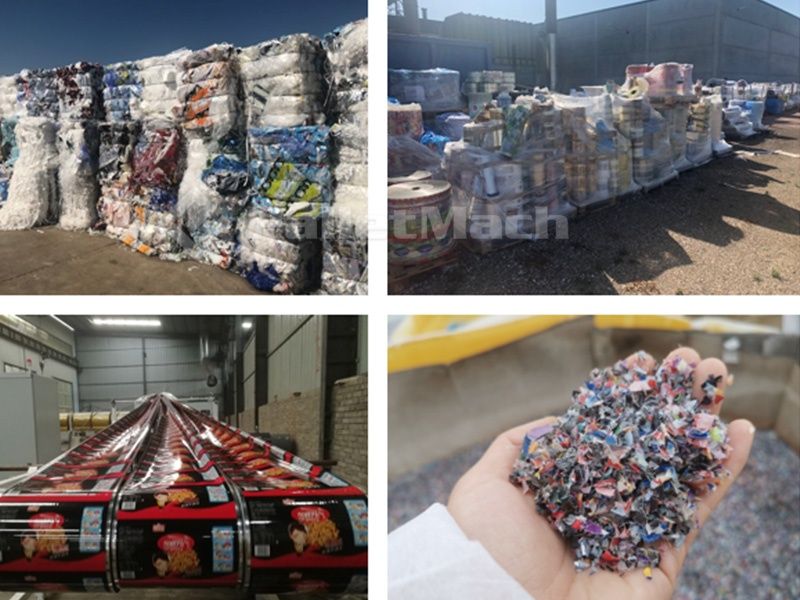

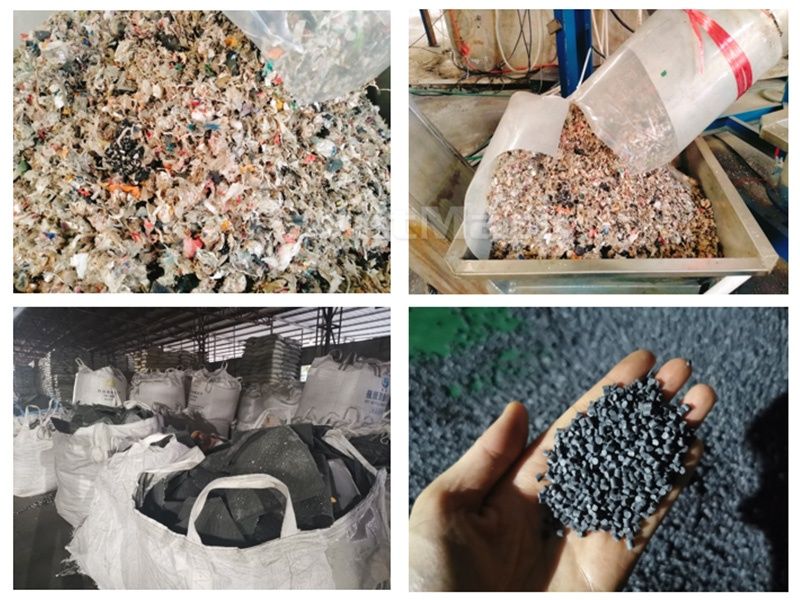

Iran

Customer's raw materials: Waste food packaging bags, plastic pallets, plastic baskets, beverage bottles (polypropylene, polyethylene, high-density polyethylene).

PalletMach's Waste Plastic Recycling Solution converted these wastes into durable plastic pallets—actual product photos showcase the remarkable results.

Spain

Customer's raw materials: Packaging waste, plastic film waste (polypropylene, polyethylene, low-density polyethylene).

Thanks to PalletMach's specialized Waste Plastic Recycling Solution, these mixed plastics were transformed into high-performance pallets (see actual product photos).

Japan

Customer's raw materials: Polyvinyl chloride, acrylonitrile-butadiene-styrene copolymer, polypropylene, wood flour.

PalletMach's versatile Waste Plastic Recycling Solution handled even complex composites, producing high-quality pallets (actual product photos available).

Mexico

Customer's raw materials: Waste plastic packaging, toothpaste tubes, etc.

Actual photos of plastic pallets made possible by PalletMach's Waste Plastic Recycling Solution.

Canada

Polyethylene pellets and plastic pallet products;

Successful debugging and samples via PalletMach's Waste Plastic Recycling Solution.

Domestic Waste Plastic Dumps: Revitalized by PalletMach's Waste Plastic Recycling Solution

Project highlights powered by PalletMach's Waste Plastic Recycling Solution:

- A government-led environmental initiative achieving "pollution source to high-value product" transformation;

- Creating a win-win for economic benefits and ecological restoration;

- Featured in a special CCTV News report—proof of the solution's impact!

Project strengths enabled by PalletMach's Waste Plastic Recycling Solution:

- Automatic plasticization and quantitative molding for efficient production;

- Unique pallet bottom design ensuring stability in long-distance transportation;

- Reduced logistics losses, boosting operational efficiency.

Cutting-Edge Technology: The 5-Step Core of PalletMach's Waste Plastic Recycling Solution

PalletMach's Waste Plastic Recycling Solution relies on advanced technology to ensure waste rebirth:

1. Intelligent Sorting: Metal detectors automatically "clear mines" to protect production lines;

2. In-Depth Purification: Multi-stage rinsing + polishing cleaning ensures purity and cleanliness;

3. Anti-Clogging Feeding: Continuous, dense feeding without bridging for smooth operations;

4. High-Pressure Cold Pressing: PalletMach presses use hydraulic-servo hybrid systems, solving traditional "roughness" issues while saving 15%-20% energy;

5. Robotic Palletizing: Fully automatic column-type robotic arms transport and stack one pallet in just 20-30 seconds.

Six Core Advantages: Why Global Customers Choose PalletMach's Waste Plastic Recycling Solution?

PalletMach's Waste Plastic Recycling Solution stands out with unmatched competitiveness:

1. Low Raw Material Requirements: Accepts various waste plastics and composites without pre-sorting, cutting raw material costs by 50-75%;

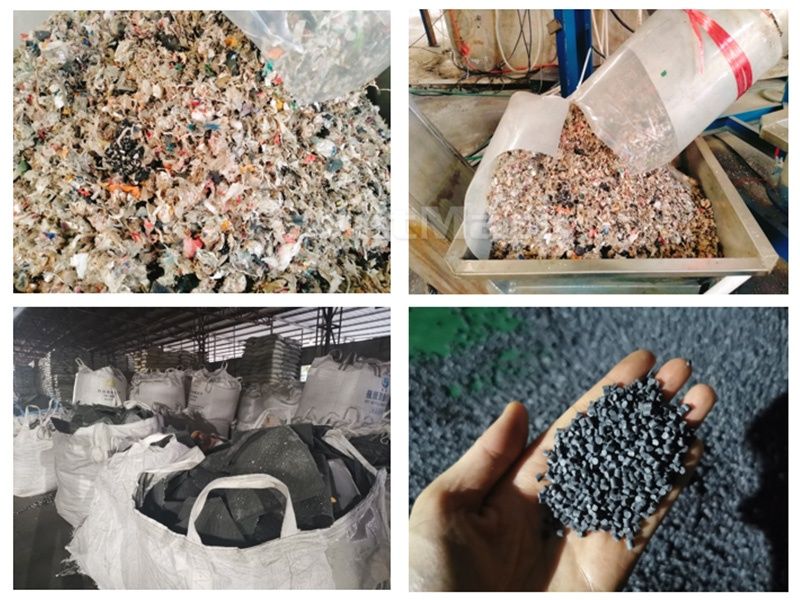

2. No Granulation Needed: Simple crushing replaces energy-intensive pelletizing, saving 35% energy—key to the solution's efficiency;

3. High Safety: Fully enclosed equipment with protective covers, complying with ISO 13857 mechanical safety standards;

4. Wide Application Range:

- Dozens of mature pallet designs solving transportation anti-slip issues;

- Pallets support 1-1.5 tons dynamic load and 4-6 tons static load;

- Extendable to produce turnover boxes, manhole covers, and more via the same solution;

5. High Automation: PLC control system with optional robotic arms reduces labor by over 70%;

6. Low Investment, High Profit: Low material/energy costs and minimal labor demand drive a comprehensive profit rate exceeding 40%.

PalletMach's Waste Plastic Recycling Solution transforms waste plastics into high-performance, high-value green molded pallets—reducing costs, expanding markets, and facilitating exports for enterprises, while enhancing economic benefits and brand value.

Tailored to diverse needs, PalletMach's Waste Plastic Recycling Solution offers customized pallets in various sizes, weights, and styles. As global plastic restriction policies tighten and the circular economy advances, the market for waste plastic molded pallets will soar. This trillion-yuan blue ocean awaits—adopt PalletMach's Waste Plastic Recycling Solution and enter the market at the perfect time!

Global Waste Plastics Transformed via PalletMach's Waste Plastic Recycling Solution

Chile

Customer's raw materials: Polyethylene sheets, crushed TV materials, and large bag materials (mainly polypropylene).

Through PalletMach's tailored Waste Plastic Recycling Solution, engineers achieved successful debugging, with high-quality pallet samples delivered.

Iran

Customer's raw materials: Waste food packaging bags, plastic pallets, plastic baskets, beverage bottles (polypropylene, polyethylene, high-density polyethylene).

PalletMach's Waste Plastic Recycling Solution converted these wastes into durable plastic pallets—actual product photos showcase the remarkable results.

Spain

Customer's raw materials: Packaging waste, plastic film waste (polypropylene, polyethylene, low-density polyethylene).

Thanks to PalletMach's specialized Waste Plastic Recycling Solution, these mixed plastics were transformed into high-performance pallets (see actual product photos).

Japan

Customer's raw materials: Polyvinyl chloride, acrylonitrile-butadiene-styrene copolymer, polypropylene, wood flour.

PalletMach's versatile Waste Plastic Recycling Solution handled even complex composites, producing high-quality pallets (actual product photos available).

Mexico

Customer's raw materials: Waste plastic packaging, toothpaste tubes, etc.

Actual photos of plastic pallets made possible by PalletMach's Waste Plastic Recycling Solution.

Canada

Polyethylene pellets and plastic pallet products;

Successful debugging and samples via PalletMach's Waste Plastic Recycling Solution.

Domestic Waste Plastic Dumps: Revitalized by PalletMach's Waste Plastic Recycling Solution

- Xinjiang Government Cooperation Project

Project highlights powered by PalletMach's Waste Plastic Recycling Solution:

- A government-led environmental initiative achieving "pollution source to high-value product" transformation;

- Creating a win-win for economic benefits and ecological restoration;

- Featured in a special CCTV News report—proof of the solution's impact!

- Shandong Paper Mill Project: Waste Plastics to Molded Pallets

Project strengths enabled by PalletMach's Waste Plastic Recycling Solution:

- Automatic plasticization and quantitative molding for efficient production;

- Unique pallet bottom design ensuring stability in long-distance transportation;

- Reduced logistics losses, boosting operational efficiency.

Cutting-Edge Technology: The 5-Step Core of PalletMach's Waste Plastic Recycling Solution

PalletMach's Waste Plastic Recycling Solution relies on advanced technology to ensure waste rebirth:

1. Intelligent Sorting: Metal detectors automatically "clear mines" to protect production lines;

2. In-Depth Purification: Multi-stage rinsing + polishing cleaning ensures purity and cleanliness;

3. Anti-Clogging Feeding: Continuous, dense feeding without bridging for smooth operations;

4. High-Pressure Cold Pressing: PalletMach presses use hydraulic-servo hybrid systems, solving traditional "roughness" issues while saving 15%-20% energy;

5. Robotic Palletizing: Fully automatic column-type robotic arms transport and stack one pallet in just 20-30 seconds.

Six Core Advantages: Why Global Customers Choose PalletMach's Waste Plastic Recycling Solution?

PalletMach's Waste Plastic Recycling Solution stands out with unmatched competitiveness:

1. Low Raw Material Requirements: Accepts various waste plastics and composites without pre-sorting, cutting raw material costs by 50-75%;

2. No Granulation Needed: Simple crushing replaces energy-intensive pelletizing, saving 35% energy—key to the solution's efficiency;

3. High Safety: Fully enclosed equipment with protective covers, complying with ISO 13857 mechanical safety standards;

4. Wide Application Range:

- Dozens of mature pallet designs solving transportation anti-slip issues;

- Pallets support 1-1.5 tons dynamic load and 4-6 tons static load;

- Extendable to produce turnover boxes, manhole covers, and more via the same solution;

5. High Automation: PLC control system with optional robotic arms reduces labor by over 70%;

6. Low Investment, High Profit: Low material/energy costs and minimal labor demand drive a comprehensive profit rate exceeding 40%.

PalletMach's Waste Plastic Recycling Solution transforms waste plastics into high-performance, high-value green molded pallets—reducing costs, expanding markets, and facilitating exports for enterprises, while enhancing economic benefits and brand value.

Tailored to diverse needs, PalletMach's Waste Plastic Recycling Solution offers customized pallets in various sizes, weights, and styles. As global plastic restriction policies tighten and the circular economy advances, the market for waste plastic molded pallets will soar. This trillion-yuan blue ocean awaits—adopt PalletMach's Waste Plastic Recycling Solution and enter the market at the perfect time!