PalletMach Wood Recycling Machine processes match factory waste into pallets in Iran

In an aging Iranian Matches Factory, the once-bustling match production line had fallen silent. As lighters replaced matches, the industry declined, leaving behind mountains of matchsticks, shavings, and offcuts. PalletMach Wood Recycling Machine turned forgotten waste into valuable resources.

Turning a Waste Burden into Competitive Advantage

“We saw wood waste as a cost—paying for disposal and losing space,” recalled the factory manager. That changed when they discovered molded pallet technology. Unlike traditional pallets, which require high-quality wood, this process is necessary only when needed—exactly what the match factory had in abundance.

The pallet samples pressed with the raw materials sent by the customer were successful, and our team visited Iran for an on-the-spot investigation.

(sample of a small pallet)

A meticulous pretreatment process

Facing varied, often damp waste wood, preprocessing is crucial.

(The customer's raw materials)

Efficient Crushing: It processed nailed wood, old pallets, and branches, crushing them to a uniform 8mm fineness. Multi-stage crushing ensured consistency for high-quality output.

(Wood Crushing Machine)

Adaptable Drying: A rotary dryer stabilized moisture to around 5%. Notably, when using MDI eco-glue, some well-preserved waste can be pressed without drying, simplifying the process and lowering investment.

(Drying Machine)

Stable and efficient pressing process

Intelligent Pressing: With its three-beam four-column design, high-precision molds, and PLC smart control, the Wood Recycling Machine ensures accurate, stable, and efficient pressing.

From crushing to pressing, the entire process became clear and controllable.

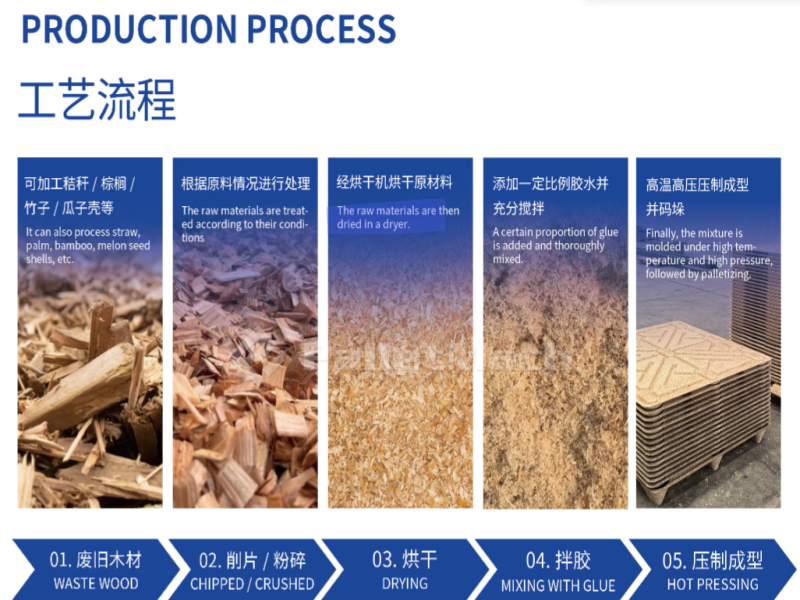

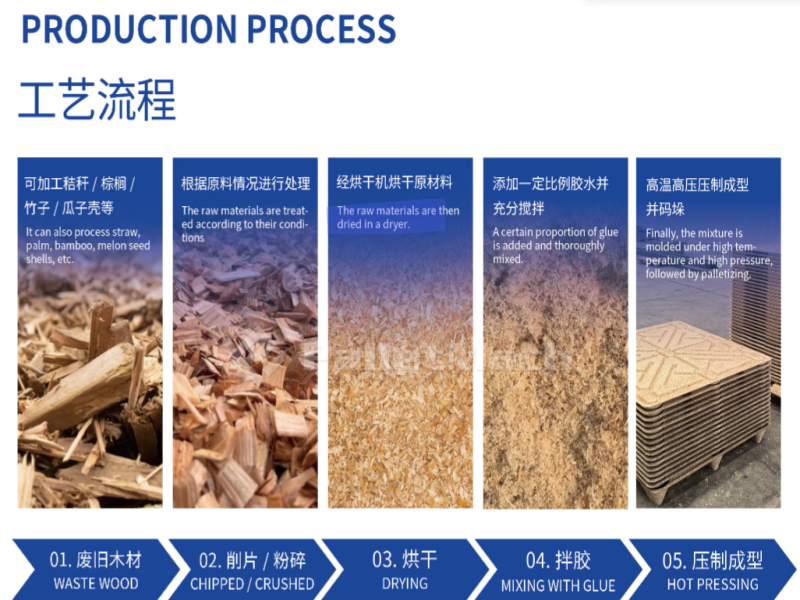

(production process)

(Wood Recycling Machine)

Soon after installation, the factory successfully produced its first batch of 1,200 x 1,000 mm pallets.

Pallet product display:

(Front)

(Back)

(Detail)

Building a Sustainable Cycle with Wood Recycling

Today, the factory has not only consumed its historical waste but also actively recycles old pallets and waste wood from the region. “What was a waste problem,” the manager notes, “is now our advantage, thanks to the Wood Recycling Machine.”

Molded wood pallets show off clear benefits in space, strength, and export:

Ready to transform your wood waste? Contact us for customized Wood Recycling Machine solutions and expert technical guidance.

Turning a Waste Burden into Competitive Advantage

“We saw wood waste as a cost—paying for disposal and losing space,” recalled the factory manager. That changed when they discovered molded pallet technology. Unlike traditional pallets, which require high-quality wood, this process is necessary only when needed—exactly what the match factory had in abundance.

The pallet samples pressed with the raw materials sent by the customer were successful, and our team visited Iran for an on-the-spot investigation.

(sample of a small pallet)

A meticulous pretreatment process

Facing varied, often damp waste wood, preprocessing is crucial.

(The customer's raw materials)

Efficient Crushing: It processed nailed wood, old pallets, and branches, crushing them to a uniform 8mm fineness. Multi-stage crushing ensured consistency for high-quality output.

(Wood Crushing Machine)

Adaptable Drying: A rotary dryer stabilized moisture to around 5%. Notably, when using MDI eco-glue, some well-preserved waste can be pressed without drying, simplifying the process and lowering investment.

(Drying Machine)

Stable and efficient pressing process

Intelligent Pressing: With its three-beam four-column design, high-precision molds, and PLC smart control, the Wood Recycling Machine ensures accurate, stable, and efficient pressing.

From crushing to pressing, the entire process became clear and controllable.

(production process)

(Wood Recycling Machine)

Soon after installation, the factory successfully produced its first batch of 1,200 x 1,000 mm pallets.

Pallet product display:

(Front)

(Back)

(Detail)

Building a Sustainable Cycle with Wood Recycling

Today, the factory has not only consumed its historical waste but also actively recycles old pallets and waste wood from the region. “What was a waste problem,” the manager notes, “is now our advantage, thanks to the Wood Recycling Machine.”

Molded wood pallets show off clear benefits in space, strength, and export:

- Space Saving: Lightweight design allows stacking up to 70% lower—e.g., 20 pallets stack to 0.75m vs. 2.7m for traditional ones.

- Load capacity: An integral reinforced structure supports dynamic loads up to 1.5 tons and static loads of 6 tons.

- Excellent design: Nail-free, rounded-corner design protects goods and workers.

- Convenient for export: The high-temperature, high-pressure process eradicates pests, eliminating fumigation. MDI glue creates a moisture-resistant “oil-film” surface with a premium finish.

Ready to transform your wood waste? Contact us for customized Wood Recycling Machine solutions and expert technical guidance.