Improve Pallet Production Efficiency With PalletMach Wooden Pallet Nailing Machine

In the manufacturing of wooden pallets, nailing is a critical step that determines the structural strength, production efficiency, and cost control of the final product. At PalletMach, we provide fast, precise, and reliable nailing machines, giving your business a competitive edge in this essential stage of production.

Advantages of PalletMach's Wooden Pallet Nailing Machines

Combines pneumatic and electric power for strong performance while reducing energy consumption. Adaptable to different pallet types and easy to maintain.

Features a PLC smart control system to accurately set the nailing path, nail quantity, and depth, ensuring consistent, high-quality, and automated production.

Cost-effective and labor-saving, delivering high efficiency with simple operation and easy management.

Compatible with Euro, American, and other international pallet standards, suitable for both domestic production and export.

We offer two main machine types: the inclined nailing machine and the horizontal nailing machine. For special production requirements, our engineering team can also provide customized solutions to meet your specific needs.

Inclined nailing machine production video

Horizontal nailing machine production video

(American standard pallet nailing machine)

(Nailing machine detail)

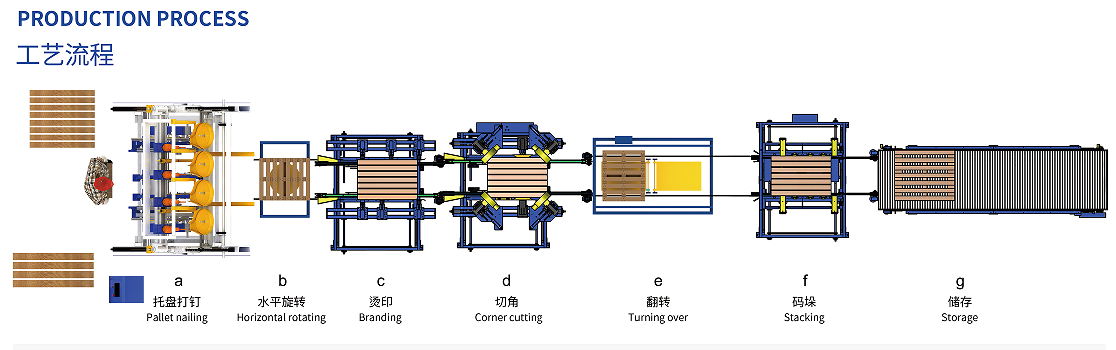

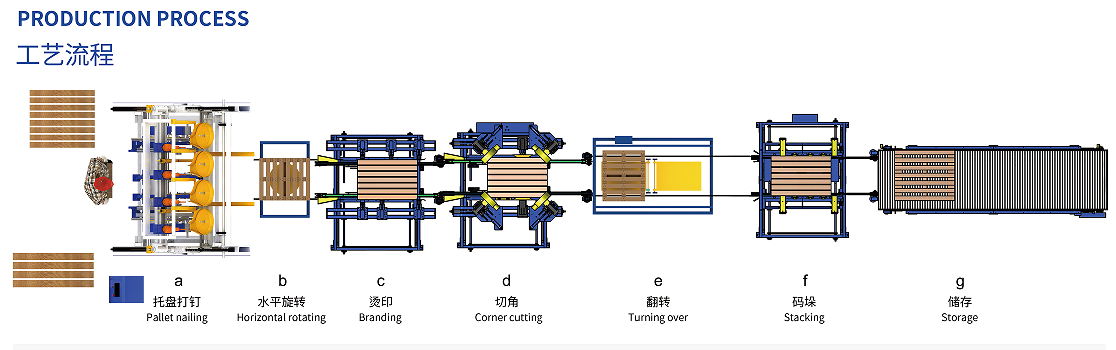

Complete Wooden Pallet Production Line

Our integrated systems cover every step of the manufacturing process, including panel cutting, block cutting, pallet leg nailing, slotting, chamfering, nailing, corner cutting, hot stamping, stacking, and more.

Beyond individual machines, we deliver complete production lines for wooden pallet manufacturing.

(Wooden pallet production process)

Under standard production conditions, one operator can produce one pallet per minute with a single machine, achieving an output of over 480 pallets per 8-hour shift.

Buying Guide

Advantages of PalletMach's Wooden Pallet Nailing Machines

Combines pneumatic and electric power for strong performance while reducing energy consumption. Adaptable to different pallet types and easy to maintain.

Features a PLC smart control system to accurately set the nailing path, nail quantity, and depth, ensuring consistent, high-quality, and automated production.

Cost-effective and labor-saving, delivering high efficiency with simple operation and easy management.

Compatible with Euro, American, and other international pallet standards, suitable for both domestic production and export.

We offer two main machine types: the inclined nailing machine and the horizontal nailing machine. For special production requirements, our engineering team can also provide customized solutions to meet your specific needs.

Inclined nailing machine production video

Horizontal nailing machine production video

(American standard pallet nailing machine)

(Nailing machine detail)

Complete Wooden Pallet Production Line

Our integrated systems cover every step of the manufacturing process, including panel cutting, block cutting, pallet leg nailing, slotting, chamfering, nailing, corner cutting, hot stamping, stacking, and more.

Beyond individual machines, we deliver complete production lines for wooden pallet manufacturing.

(Wooden pallet production process)

Under standard production conditions, one operator can produce one pallet per minute with a single machine, achieving an output of over 480 pallets per 8-hour shift.

Buying Guide

- Define Your Needs

- Understand the Wooden Pallet Nailing Machine

- Gradually Expand Production Scale

- See It for Yourself