The PalletMach wind turbine blade recycling machine converts blade waste into pallets

As the global wind power industry expands, the disposal of a large number of waste wind turbine blades has become a pressing environmental challenge. Traditional landfill methods not only consume land resources but also risk contaminating soil and groundwater. The PalletMach Wind Turbine Blade Recycling Machine addresses this exact problem – through innovative technology, it transforms discarded wind turbine blades into high-value, molded pallets.

Why Are Wind Turbine Blades Hard to Dispose of?

Wind turbine blades are primarily made of thermosetting composite materials such as fiber-reinforced plastic (FRP). These materials boast high strength but are extremely difficult to degrade. Direct landfilling without proper treatment would impose long-term environmental burdens.

(Wind turbines)

(Abandoned wind turbine blades)

PalletMach’s Solution: Wind Turbine Blade Recycling Machine

At the heart of PalletMach's solution is a specialized wind turbine blade recycling machine. It employs an integrated multi-stage process—including crushing, sorting, and remanufacturing—to transform this industrial waste into eco-friendly pallets.

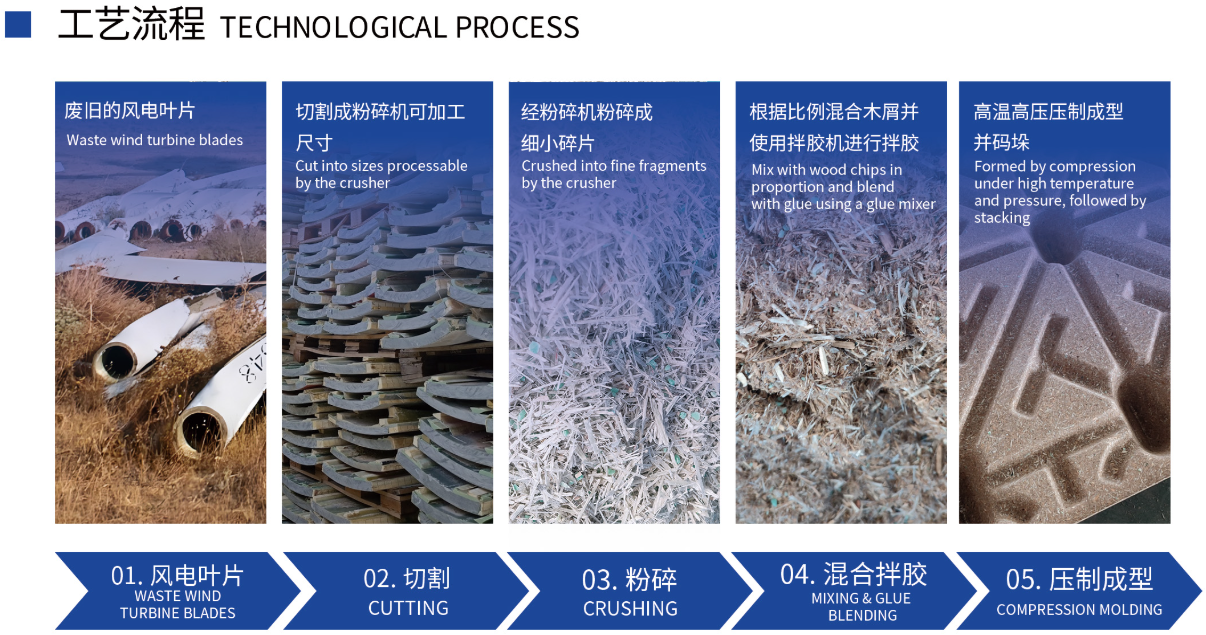

Production Process:

Waste blades → Cutting → Crushing → Mixing with wood chips → High-temperature and high-pressure molding via wind turbine blade recycling machine → Automatic palletizing.

(Processed raw materials)

The entire process uses eco-friendly MDI adhesives with zero formaldehyde addition, complying with international environmental standards.

Core Advantages of the Wind Turbine Blade Recycling Machine

- High Precision

The wind blade recycling machine adopts a vertical four-column hydraulic press structure. Its frame features a three-beam four-column design, delivering excellent strength, rigidity, and precision retention.

- High Automation

The wind blade recycling machine integrates mechanical, pneumatic, and electrical technologies. Each operation sequence is controlled by a PLC system, with a user-friendly touchscreen interface for easy operation. The entire pallet molding equipment and production process are energy-efficient, eco-friendly, and highly automated, significantly reducing labor costs.

- Low Cost

Raw materials are waste Wind Turbine Blade, lowering production costs substantially. Their price is lower than that of the raw materials used in traditional wood pallet production.

(wind blade recycling machine)

- Superior Quality of products

The molded pallets produced by the machine match the quality of traditional pallets while saving 60% of storage space thanks to their one-piece molding design. The rounded corner design protects goods from damage, and the pallets can be directly exported without fumigation. Benefiting from the glass fiber reinforcement inherent in wind turbine blades, the pallets have a static load capacity of 4–6 tons and a dynamic load capacity of 1.5–2 tons.

(The front of the pallet)

(The back of the pallet)

(Detail of the pallet)

In addition to the "wind turbine blade + wood chip" combination, the recycled material can also be mixed with plastics to produce high-strength plastic molded pallets, which fully meet the application needs of various complex scenarios such as logistics, warehousing, and cold chain distribution.

PalletMach has helped many enterprises realize the resource regeneration of waste wind turbine blades. Please feel free to contact us.