How Double Deck Compressed Wood Pallets Save Costs in Warehousing

In the fast-paced world of logistics and warehousing, efficiency is synonymous with profit. Every decision, from layout design to the choice of equipment, impacts the bottom line. While lightweight, compressed wood pallets are popular for floor storage and shipping, they reveal significant weaknesses in racking environments—a challenge that directly increases operational costs and safety risks.

The Hidden Cost of the "Racking Problem"

Standard compressed wood pallets are not built for racking systems. Their supporting feet cannot bear the load on the shelf beams; only the thin edges of the top deck can. This drastically reduces their safe load capacity and creates a high risk of tilting or collapsing.

(Selective Pallet Racking)

(The edges of a standard compressed wood pallet)

The consequences are clear:

* You cannot utilize the full weight capacity of your racking.

* Potential for product damage, pallet failure, and even workplace accidents.

* Operators must be extra cautious, slowing down load/unload times.

The Solution: PalletMach Double Deck Compressed Wood Pallets

The solution is as elegant as it is effective. By combining two compressed wood pallets and securely fastening them together, we create a robust, unified structure. This PalletMach Double Deck Compressed Wood Pallets system is engineered specifically for racking applications.

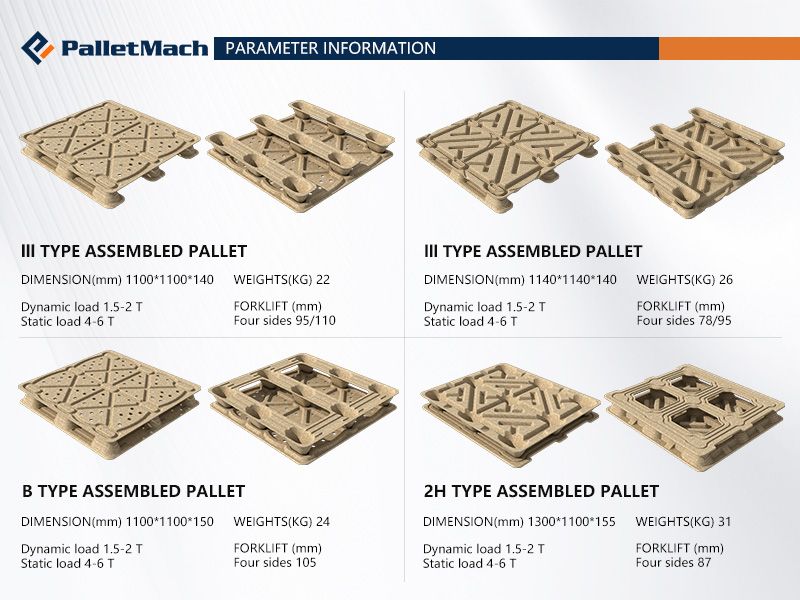

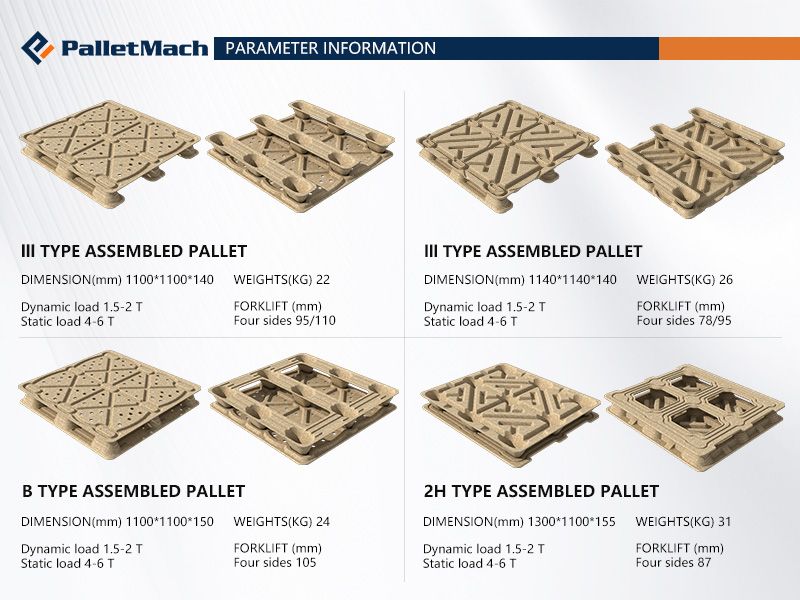

(A type of PalletMach Double Deck Compressed Wood Pallets)

How PalletMach Double Deck Compressed Wood Pallets Directly Save You Money

1. Maximizes Racking Utilization & Saves Space

A PalletMach Double Deck Compressed Wood Pallets distributes weight evenly across the entire shelf beam. This allows you to safely load pallets to the full weight capacity of your racking system. By storing more goods per pallet position, you increase storage density, potentially delaying or eliminating the need for costly warehouse expansion.

2. Enhances Safety and Reduces Losses

The reinforced structure of the PalletMach Double Deck Compressed Wood Pallets eliminates flexing and the risk of collapse. This creates a safer working environment, reducing the likelihood of costly accidents, product damage, and associated insurance claims. You save money by protecting both your inventory and your people.

3. Improves Operational Efficiency

A stable pallet is a fast pallet. Forklift operators can move and place PalletMach Double Deck Compressed Wood Pallets with confidence and speed, without worrying about load shifts. This streamlines inbound and outbound workflows, reduces handling time, and boosts overall warehouse throughput.

4. Delivers Long-Term Durability and ROI

Constructed from high-strength, compressed wood, these pallets are built to last. They are resistant to moisture, pests, and decay, ensuring a long service life even in demanding conditions. The durability of PalletMach Double Deck Compressed Wood Pallets means fewer replacements and lower long-term material costs.

5. Offers Customizable, Future-Proof Solutions

Every warehouse is unique. The modular nature of the PalletMach Double Deck Compressed Wood Pallets design allows for customization—mixing different top and bottom deck styles to meet specific load requirements and racking specifications. This flexibility ensures you get a cost-effective solution tailored to your exact needs.

We offer various combination options. Different types of compressed wood pallets can be freely combined.

A Complete Ecosystem for Production

To maximize cost savings, our partners can leverage a full suite of production equipment—from wood pallet machine and pallet block machine to Automatic screw locking machine and wood pallet block cutting machine. This integrated approach minimizes labor, ensures consistent quality, and drives down the total cost of ownership for your pallet supply.

Are you ready to discover how PalletMach Double Deck Compressed Wood Pallets can optimize your storage and reduce your costs? Contact our team today for a personalized analysis and custom solution tailored to your operation.

The Hidden Cost of the "Racking Problem"

Standard compressed wood pallets are not built for racking systems. Their supporting feet cannot bear the load on the shelf beams; only the thin edges of the top deck can. This drastically reduces their safe load capacity and creates a high risk of tilting or collapsing.

(Selective Pallet Racking)

(The edges of a standard compressed wood pallet)

The consequences are clear:

* You cannot utilize the full weight capacity of your racking.

* Potential for product damage, pallet failure, and even workplace accidents.

* Operators must be extra cautious, slowing down load/unload times.

The Solution: PalletMach Double Deck Compressed Wood Pallets

The solution is as elegant as it is effective. By combining two compressed wood pallets and securely fastening them together, we create a robust, unified structure. This PalletMach Double Deck Compressed Wood Pallets system is engineered specifically for racking applications.

(A type of PalletMach Double Deck Compressed Wood Pallets)

How PalletMach Double Deck Compressed Wood Pallets Directly Save You Money

1. Maximizes Racking Utilization & Saves Space

A PalletMach Double Deck Compressed Wood Pallets distributes weight evenly across the entire shelf beam. This allows you to safely load pallets to the full weight capacity of your racking system. By storing more goods per pallet position, you increase storage density, potentially delaying or eliminating the need for costly warehouse expansion.

2. Enhances Safety and Reduces Losses

The reinforced structure of the PalletMach Double Deck Compressed Wood Pallets eliminates flexing and the risk of collapse. This creates a safer working environment, reducing the likelihood of costly accidents, product damage, and associated insurance claims. You save money by protecting both your inventory and your people.

3. Improves Operational Efficiency

A stable pallet is a fast pallet. Forklift operators can move and place PalletMach Double Deck Compressed Wood Pallets with confidence and speed, without worrying about load shifts. This streamlines inbound and outbound workflows, reduces handling time, and boosts overall warehouse throughput.

4. Delivers Long-Term Durability and ROI

Constructed from high-strength, compressed wood, these pallets are built to last. They are resistant to moisture, pests, and decay, ensuring a long service life even in demanding conditions. The durability of PalletMach Double Deck Compressed Wood Pallets means fewer replacements and lower long-term material costs.

5. Offers Customizable, Future-Proof Solutions

Every warehouse is unique. The modular nature of the PalletMach Double Deck Compressed Wood Pallets design allows for customization—mixing different top and bottom deck styles to meet specific load requirements and racking specifications. This flexibility ensures you get a cost-effective solution tailored to your exact needs.

We offer various combination options. Different types of compressed wood pallets can be freely combined.

A Complete Ecosystem for Production

To maximize cost savings, our partners can leverage a full suite of production equipment—from wood pallet machine and pallet block machine to Automatic screw locking machine and wood pallet block cutting machine. This integrated approach minimizes labor, ensures consistent quality, and drives down the total cost of ownership for your pallet supply.

Are you ready to discover how PalletMach Double Deck Compressed Wood Pallets can optimize your storage and reduce your costs? Contact our team today for a personalized analysis and custom solution tailored to your operation.