Food Packaging Recycling Machine Transforms Waste into Custom Pallets

Faced with mounting warehouse and management pressures caused by large amounts of daily waste plastic packaging, a leading Iranian food company was actively seeking a sustainable circular economy solution. Ultimately, PalletMach won the customer’s trust by offering an innovative food packaging recycling machine that produces colored plastic pallets from recycled materials.

PART 1: Partnership Established

In June 2022, this leading candy manufacturer signed a contract with PalletMach to introduce a fully automated food packaging recycling machine for manufacturing colored plastic pallets, enabling large-scale and resourceful recycling of waste plastic.

The integrated food packaging recycling machine covers the entire process—crushing, washing, sorting, drying, plasticizing, and quantitative molding—to produce international standard (1200×1000×145mm) colored plastic pallets. Each pallet weighs approximately 18kg and offers a dynamic load capacity of 1 ton and a static load of 4-6 tons, making these pallets ideal for high-intensity, high-hygiene logistics environments in the food industry.

With high automation and continuity, the food packaging recycling machine produces 400 colored plastic pallets per day within a footprint of just 1,000 square meters. Compared to traditional injection molding, this system reduces initial investment, saves energy, cuts labor costs, and enhances both economic and environmental performance.

PART 2: Project Highlights

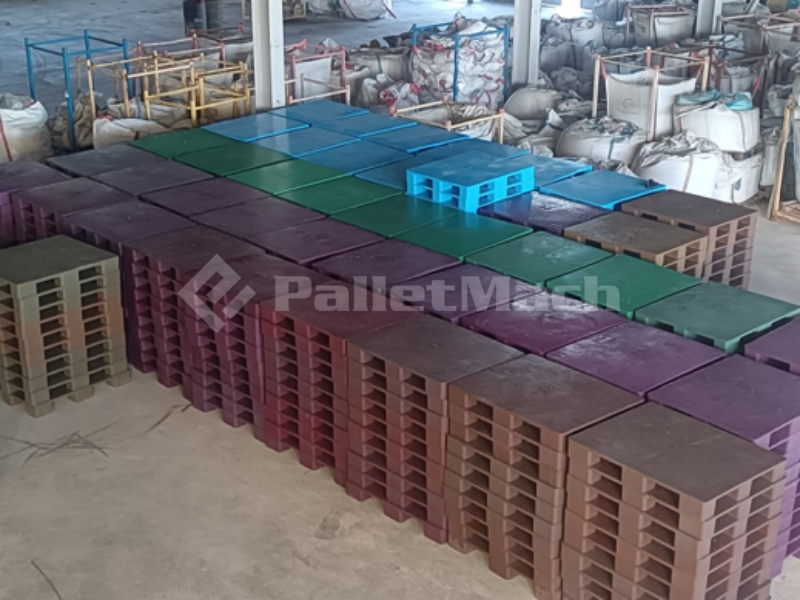

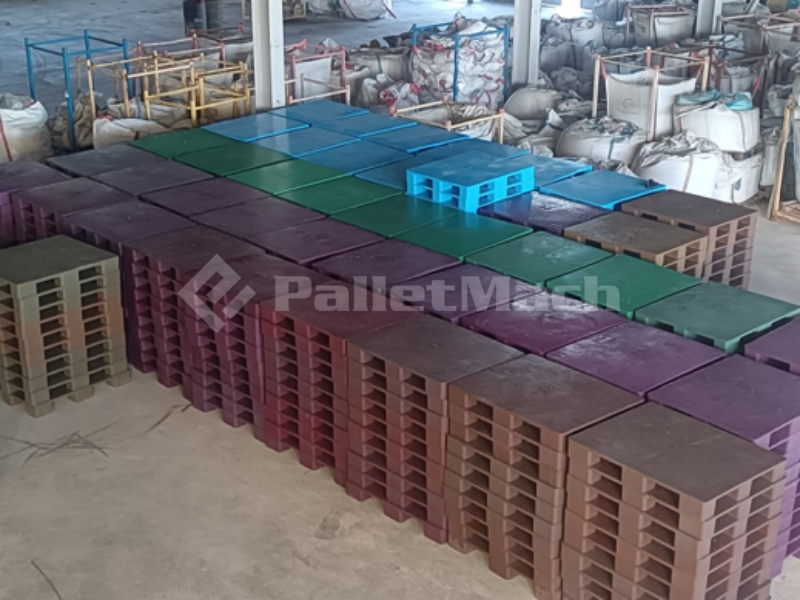

Color Recognition Through Colored Plastic Pallets

A standout innovation of the food packaging recycling machine is its ability to process inherently colorful waste plastics—from food packaging, bottles, crates, and damaged pallets—as raw material. By turning this waste directly into colored plastic pallets, visual management is seamlessly integrated into warehouse operations.

These colored plastic pallets support functional zoning:

Red colored plastic pallets: indicate urgent or high-risk materials

(Molded Plastic Pallet)

Green colored plastic pallets represent certified, eco-friendly products

(Molded Plastic Pallet)

Such color-coded logistics improve zoning, picking, and distribution accuracy while paving the way for digital warehouse management.

High Customization

Beyond color, the food packaging recycling machine supports full customization of pallets in size, structure, thickness, weight, and load performance, including:

(Back of Pallet)

(Pallet Pattern)

PART 3: Conclusion

From Candy to Shelf

This project not only solves waste plastic challenges through the food packaging recycling machine, but turns recycled material into high-value colored plastic pallets, achieving both economic and environmental wins. The company now internally uses and externally sells these pallets, extending their value chain and strengthening their integrated “from candy to shelf” strategy.

Take Action Now

If your business seeks to reduce waste or build an efficient, low-carbon pallet operation, contact PalletMach today. We deliver customized food packaging recycling machine solutions—combining professional technology and equipment to drive green and intelligent transformation!

PART 1: Partnership Established

In June 2022, this leading candy manufacturer signed a contract with PalletMach to introduce a fully automated food packaging recycling machine for manufacturing colored plastic pallets, enabling large-scale and resourceful recycling of waste plastic.

(Raw Material)

The integrated food packaging recycling machine covers the entire process—crushing, washing, sorting, drying, plasticizing, and quantitative molding—to produce international standard (1200×1000×145mm) colored plastic pallets. Each pallet weighs approximately 18kg and offers a dynamic load capacity of 1 ton and a static load of 4-6 tons, making these pallets ideal for high-intensity, high-hygiene logistics environments in the food industry.

With high automation and continuity, the food packaging recycling machine produces 400 colored plastic pallets per day within a footprint of just 1,000 square meters. Compared to traditional injection molding, this system reduces initial investment, saves energy, cuts labor costs, and enhances both economic and environmental performance.

PART 2: Project Highlights

Color Recognition Through Colored Plastic Pallets

A standout innovation of the food packaging recycling machine is its ability to process inherently colorful waste plastics—from food packaging, bottles, crates, and damaged pallets—as raw material. By turning this waste directly into colored plastic pallets, visual management is seamlessly integrated into warehouse operations.

These colored plastic pallets support functional zoning:

Red colored plastic pallets: indicate urgent or high-risk materials

(Molded Plastic Pallet)

Green colored plastic pallets represent certified, eco-friendly products

(Molded Plastic Pallet)

Such color-coded logistics improve zoning, picking, and distribution accuracy while paving the way for digital warehouse management.

High Customization

Beyond color, the food packaging recycling machine supports full customization of pallets in size, structure, thickness, weight, and load performance, including:

- Tailored dimensions for shelves, automated systems, and forklifts

- Reinforced ribs for heavy stacking

- Anti-slip bottom patterns for safe transport and stable stacking

- Custom limit slot for easy fixation

- robotic and unmanned handling

- Dynamic load capacity of up to 2.5 tons

(Back of Pallet)

(Pallet Pattern)

PART 3: Conclusion

From Candy to Shelf

This project not only solves waste plastic challenges through the food packaging recycling machine, but turns recycled material into high-value colored plastic pallets, achieving both economic and environmental wins. The company now internally uses and externally sells these pallets, extending their value chain and strengthening their integrated “from candy to shelf” strategy.

Take Action Now

If your business seeks to reduce waste or build an efficient, low-carbon pallet operation, contact PalletMach today. We deliver customized food packaging recycling machine solutions—combining professional technology and equipment to drive green and intelligent transformation!