PalletMach Pioneers Waste Mulch Film Recycle Solution in Xinjiang

A partnership between the China Academy of Agricultural Sciences Cotton Research Institute and Henan PalletMach has successfully implemented a comprehensive cotton field waste treatment system in Jinghe County. Utilizing cutting-edge crushing, dry separation, and automation technology, the project achieved a crucial breakthrough: precise separation of cotton stalks and residual film. This process enables the efficient recycling of waste mulch film, turning a stubborn pollutant into a valuable resource.

(raw materials)

Now, an innovative solution is making a major impact: converting both types of waste into high-value, eco-friendly pallets. Central to this solution is an efficient system for large-scale waste mulch film recycling.

For years, cotton stalks were typically shredded and returned to the fields. However, Xinjiang’s dry climate slows decomposition, disrupting sowing in the following season. At the same time, the difficulty of recycling waste mulch film—often entangled with plant matter—posed a globally recognized environmental and technical problem.

In the vast cotton fields of Xinjiang, the autumn harvest yields not only a bounty of cotton but also significant challenges: millions of tons of cotton stalks and the persistent issue of "white pollution" from waste mulch film. Effectively managing and recycling this waste mulch film has long been a critical concern for sustainable agriculture.

(plant fiber molded pallets)

(mulch film pallet)

As a specialist in fiber and plastic molding solutions, PalletMach helps achieve both environmental and economic goals by converting challenging waste into useful products. The operation processes roughly 100 tons of waste per day, producing 100 plastic pallets and 300 stalk-based pallets—truly turning waste into treasure.

Environmental benefits are substantial: reducing white pollution, improving soil quality, and supporting sustainable farming practices. The economic advantages are equally clear: low processing costs and new revenue sources.

This Xinjiang-based initiative has gained strong government support, attracted inspection teams from across China, and been featured on CCTV News.

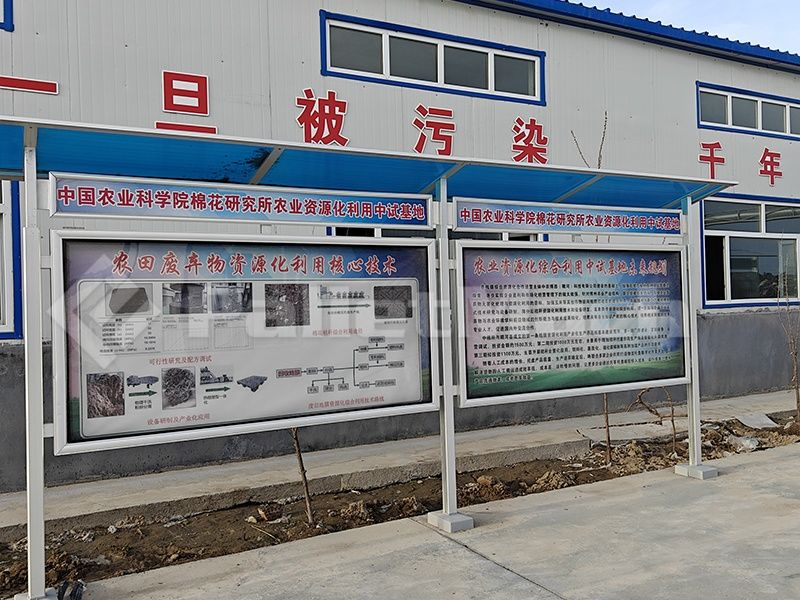

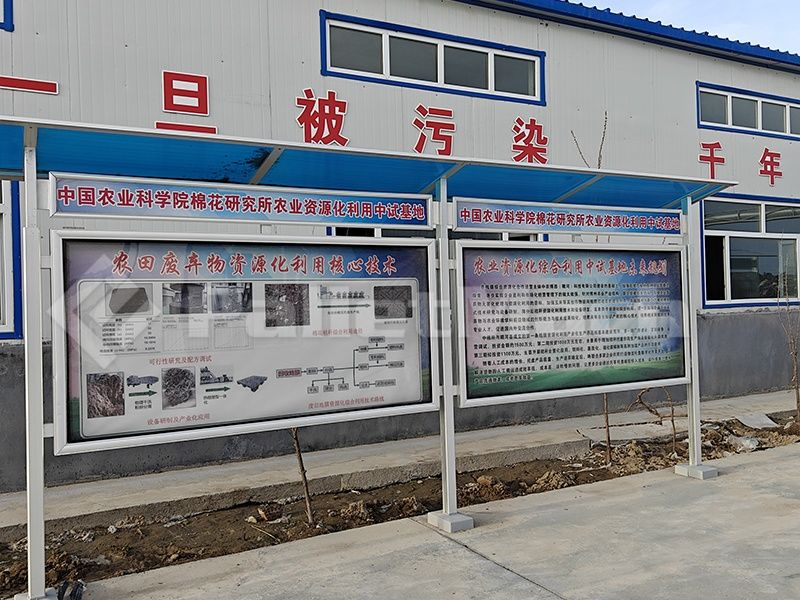

(Xinjiang plant bulletin board)

This waste revolution showcases a new model for agricultural modernization—where technology transforms waste into resources, achieving a balance between ecological and economic benefits. It provides a scalable template for waste mulch film recycling and agricultural waste management nationwide and beyond.

The project is a real-world example of the principle that “green mountains and clear waters are invaluable assets.” As technology evolves, more agricultural waste will find new life as valuable resources, advancing green development and rural revitalization.

If you are dealing with straw, waste mulch film, or other agricultural waste streams, scan the QR code below to consult with our experts. Let’s collaborate to turn waste into valuable, eco-friendly pallets!

(raw materials)

Now, an innovative solution is making a major impact: converting both types of waste into high-value, eco-friendly pallets. Central to this solution is an efficient system for large-scale waste mulch film recycling.

For years, cotton stalks were typically shredded and returned to the fields. However, Xinjiang’s dry climate slows decomposition, disrupting sowing in the following season. At the same time, the difficulty of recycling waste mulch film—often entangled with plant matter—posed a globally recognized environmental and technical problem.

In the vast cotton fields of Xinjiang, the autumn harvest yields not only a bounty of cotton but also significant challenges: millions of tons of cotton stalks and the persistent issue of "white pollution" from waste mulch film. Effectively managing and recycling this waste mulch film has long been a critical concern for sustainable agriculture.

- So, what happens to the cotton stalks?

(plant fiber molded pallets)

- As for the waste mulch film?

(mulch film pallet)

As a specialist in fiber and plastic molding solutions, PalletMach helps achieve both environmental and economic goals by converting challenging waste into useful products. The operation processes roughly 100 tons of waste per day, producing 100 plastic pallets and 300 stalk-based pallets—truly turning waste into treasure.

Environmental benefits are substantial: reducing white pollution, improving soil quality, and supporting sustainable farming practices. The economic advantages are equally clear: low processing costs and new revenue sources.

This Xinjiang-based initiative has gained strong government support, attracted inspection teams from across China, and been featured on CCTV News.

(Xinjiang plant bulletin board)

This waste revolution showcases a new model for agricultural modernization—where technology transforms waste into resources, achieving a balance between ecological and economic benefits. It provides a scalable template for waste mulch film recycling and agricultural waste management nationwide and beyond.

The project is a real-world example of the principle that “green mountains and clear waters are invaluable assets.” As technology evolves, more agricultural waste will find new life as valuable resources, advancing green development and rural revitalization.

If you are dealing with straw, waste mulch film, or other agricultural waste streams, scan the QR code below to consult with our experts. Let’s collaborate to turn waste into valuable, eco-friendly pallets!