Turn Paper Mill Waste into Plastic Pallets with PalletMach’Green Solution

For large, continuously operating paper mills, the production of paper is inevitably accompanied by the generation of tons of Paper Mill Waste. These mountains of "garbage" pose a significant disposal challenge. But for forward-thinking clients, this Paper Mill Waste is not a burden—it's an untapped urban mine, brimming with potential.

PalletMach, with proven project experience in China, the Philippines, and other locations worldwide, partnered with forward-thinking clients to harness this potential. Together, we are launching a new production line dedicated to transforming Paper Mill Waste into high-value, plastic-molded pallets.

From Waste to Wealth: The Raw Material Goldmine

The high content of waste plastic within Paper Mill Waste presents a clear opportunity. Instead of seeing a disposal problem, we see a readily available, low-cost "raw material reserve" waiting to be unlocked.

With the successful completion of our pilot test using Paper Mill Waste, the path for a stable and high-quality raw material supply for future pallet production is now clear, demonstrating significant economic and environmental value.

Click the link below to watch the trial video of the Paper Mill Waste:

Turn Paper Mill Waste into Profit with PalletMach - YouTube

The PalletMach Solution: Overcoming the Challenges of Paper Mill Waste

The composition of Paper Mill Waste is complex and has a high impurity content, with processing difficulties focused on washing, separation, and plastification. Our tailored process conquers these challenges:

Shredding + Multi-Stage Washing + Paper-Plastic Separation: This phase progressively removes impurities like sand, paper fibers, and metals, ensuring the plastic purity meets stringent production requirements.

(Paper Mill Waste)

Drying and Plastification: We efficiently process wet material with 40-50% moisture content down to ≤5% in a single step, while achieving preliminary plastification to form uniform pellets, laying the groundwork for extrusion.

Multi-Stage Extruder + Quantitative Storage: Our multi-stage extrusion system ensures complete plastification and degassing. Coupled with our uniquely designed quantitative feeding system, it guarantees precise material control and product consistency.

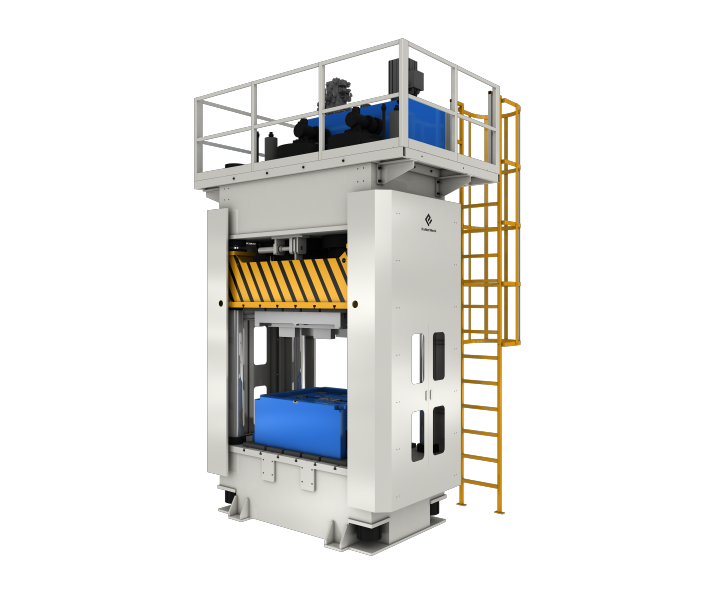

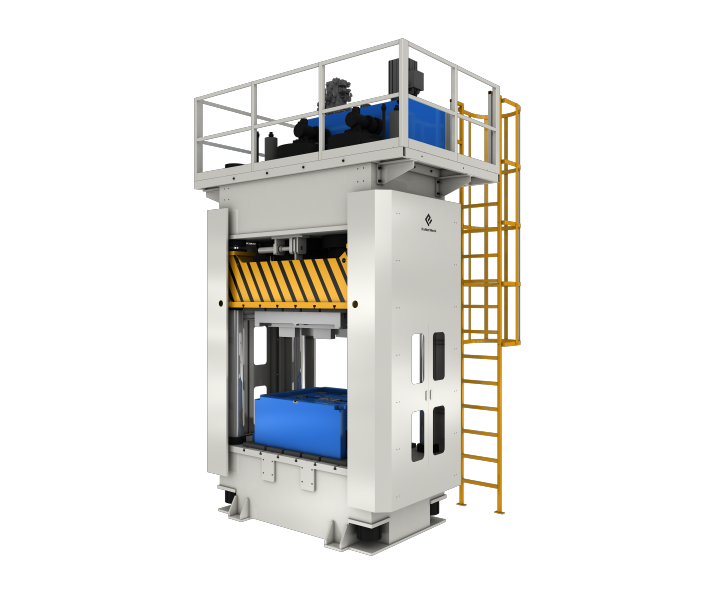

PalletMach plastic machine + Custom Molds: Our high-tonnage cold-pressing technology, combined with automatic mold systems with built-in cooling channels, enables rapid pressure holding (120-180s) and efficient demolding.

(PalletMach plastic machine)

The Core Wealth Code: 3 Unbeatable Advantages

Transforming Paper Mill Waste into plastic pallets unlocks a powerful profit model built on three core advantages:

1. Nearly Free, Abundant Raw Materials: Through rational recycling, paper mills can secure a long-term, stable, and massive source of raw materials from their Paper Mill Waste at minimal cost. The profit margin is clear and substantial.

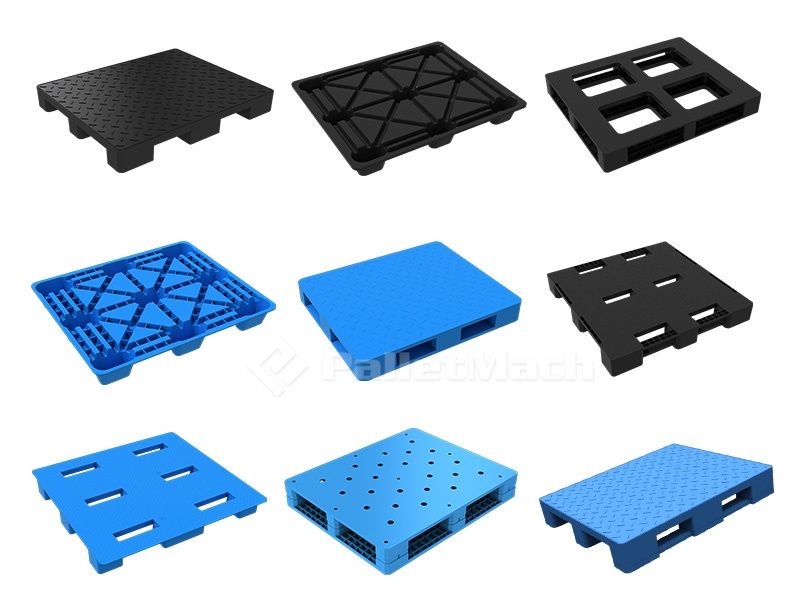

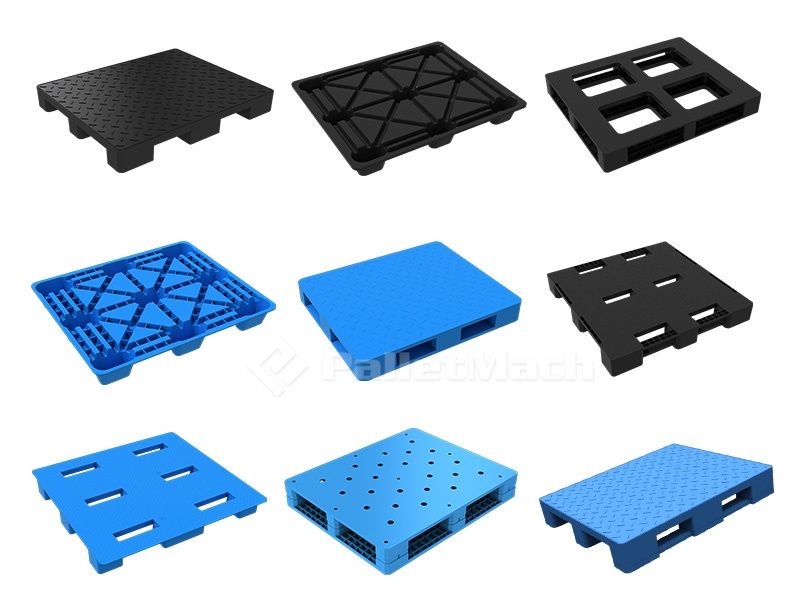

2. Rapid and Considerable Market Return: Leveraging PalletMach's mature process, every 500kg of Paper Mill Waste can be efficiently converted into approximately 20 standard pallets. With the international market price for mixed raw material plastic pallets ranging from $30 to $45 per piece, each production batch translates into fast and considerable returns.

(Rich variety of plastic pallet designs)

3. Proven ROI and Long-Term Profitability: PalletMach equipment, built with precision-cast components for superior durability, boasts a service life exceeding 10 years (with some client units running stably for over 15 years). Based on this low-operating-cost and high-value-output model, our clients can potentially recoup their investment within 1 year, generating pure profit for years to come.

The journey of managing Paper Mill Waste ends here, and the journey of profitability begins. By investing in a PalletMach pallet production line, you are not just solving a waste problem—you are building a new, profitable business unit from the ground up.

Ready to explore how to turn your Paper Mill Waste into a revenue stream? Contact our experts today for a free consultation and project analysis.

PalletMach, with proven project experience in China, the Philippines, and other locations worldwide, partnered with forward-thinking clients to harness this potential. Together, we are launching a new production line dedicated to transforming Paper Mill Waste into high-value, plastic-molded pallets.

From Waste to Wealth: The Raw Material Goldmine

The high content of waste plastic within Paper Mill Waste presents a clear opportunity. Instead of seeing a disposal problem, we see a readily available, low-cost "raw material reserve" waiting to be unlocked.

With the successful completion of our pilot test using Paper Mill Waste, the path for a stable and high-quality raw material supply for future pallet production is now clear, demonstrating significant economic and environmental value.

Click the link below to watch the trial video of the Paper Mill Waste:

Turn Paper Mill Waste into Profit with PalletMach - YouTube

The PalletMach Solution: Overcoming the Challenges of Paper Mill Waste

The composition of Paper Mill Waste is complex and has a high impurity content, with processing difficulties focused on washing, separation, and plastification. Our tailored process conquers these challenges:

Shredding + Multi-Stage Washing + Paper-Plastic Separation: This phase progressively removes impurities like sand, paper fibers, and metals, ensuring the plastic purity meets stringent production requirements.

(Paper Mill Waste)

Drying and Plastification: We efficiently process wet material with 40-50% moisture content down to ≤5% in a single step, while achieving preliminary plastification to form uniform pellets, laying the groundwork for extrusion.

Multi-Stage Extruder + Quantitative Storage: Our multi-stage extrusion system ensures complete plastification and degassing. Coupled with our uniquely designed quantitative feeding system, it guarantees precise material control and product consistency.

PalletMach plastic machine + Custom Molds: Our high-tonnage cold-pressing technology, combined with automatic mold systems with built-in cooling channels, enables rapid pressure holding (120-180s) and efficient demolding.

(PalletMach plastic machine)

The Core Wealth Code: 3 Unbeatable Advantages

Transforming Paper Mill Waste into plastic pallets unlocks a powerful profit model built on three core advantages:

1. Nearly Free, Abundant Raw Materials: Through rational recycling, paper mills can secure a long-term, stable, and massive source of raw materials from their Paper Mill Waste at minimal cost. The profit margin is clear and substantial.

2. Rapid and Considerable Market Return: Leveraging PalletMach's mature process, every 500kg of Paper Mill Waste can be efficiently converted into approximately 20 standard pallets. With the international market price for mixed raw material plastic pallets ranging from $30 to $45 per piece, each production batch translates into fast and considerable returns.

(Rich variety of plastic pallet designs)

3. Proven ROI and Long-Term Profitability: PalletMach equipment, built with precision-cast components for superior durability, boasts a service life exceeding 10 years (with some client units running stably for over 15 years). Based on this low-operating-cost and high-value-output model, our clients can potentially recoup their investment within 1 year, generating pure profit for years to come.

The journey of managing Paper Mill Waste ends here, and the journey of profitability begins. By investing in a PalletMach pallet production line, you are not just solving a waste problem—you are building a new, profitable business unit from the ground up.

Ready to explore how to turn your Paper Mill Waste into a revenue stream? Contact our experts today for a free consultation and project analysis.