Reduce Raw Material Costs with PalletMach Agricultural Waste Equipment

In recent years, the global price of timber raw materials used for manufacturing pallets has experienced significant increases and severe fluctuations. Impacts from the pandemic, supply chain disruptions, competition for raw materials with the construction industry, and climate issues, such as the Canadian wildfires, have collectively driven timber prices to historically high levels. In this context, PalletMach Agricultural Waste Equipment provides a fundamental solution: by converting waste resources into high-performance pallets, it alleviates raw material cost pressures at the source.

Raw Material Revolution

Traditional wooden pallets are constrained by the price of raw timber, resulting in high and uncontrollable cost fluctuations. The core innovation of PalletMach Agricultural Waste Equipment lies in its ability to use widely available agricultural and forestry waste as its primary "feed," completely eliminating reliance on timber.

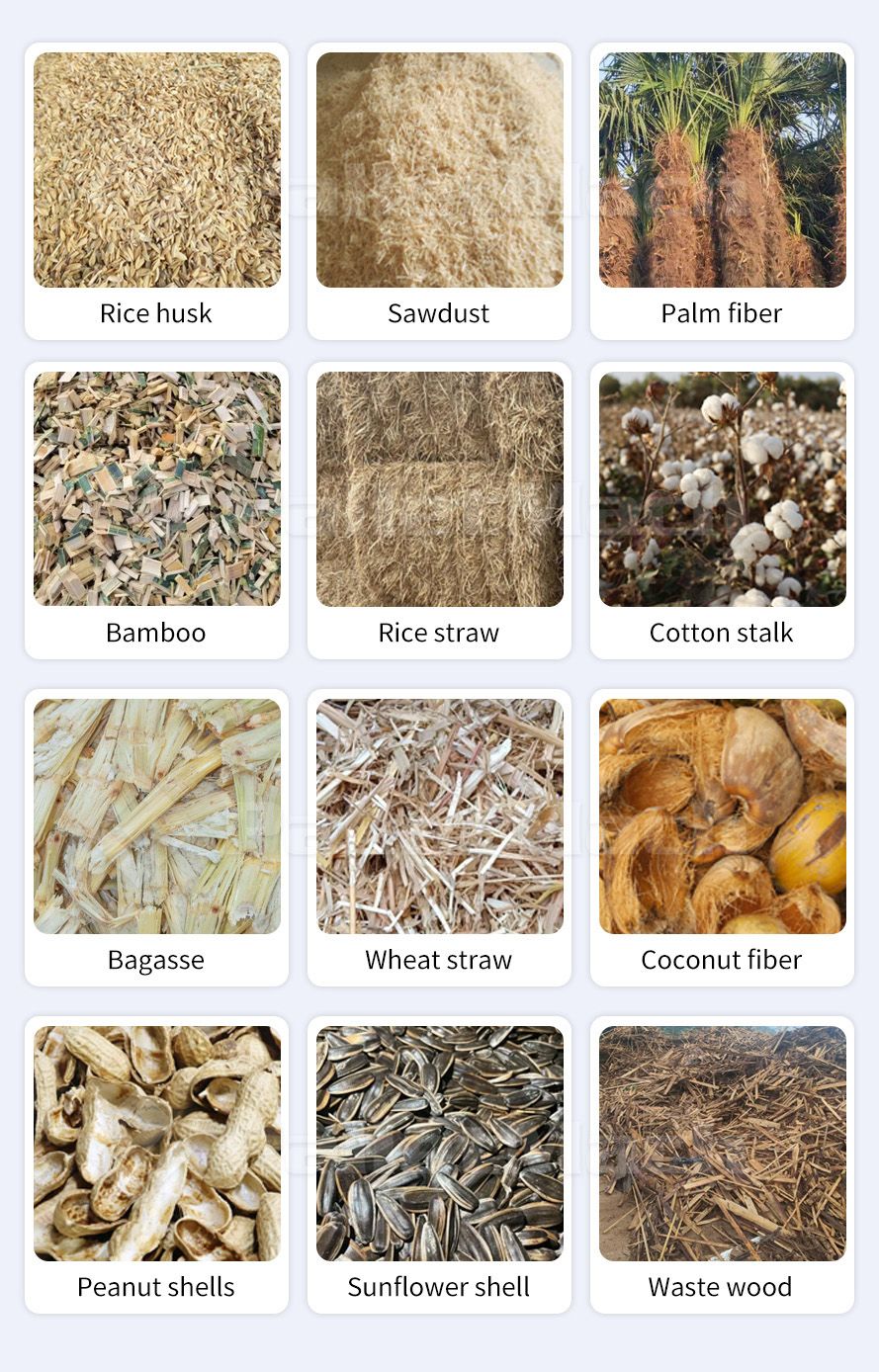

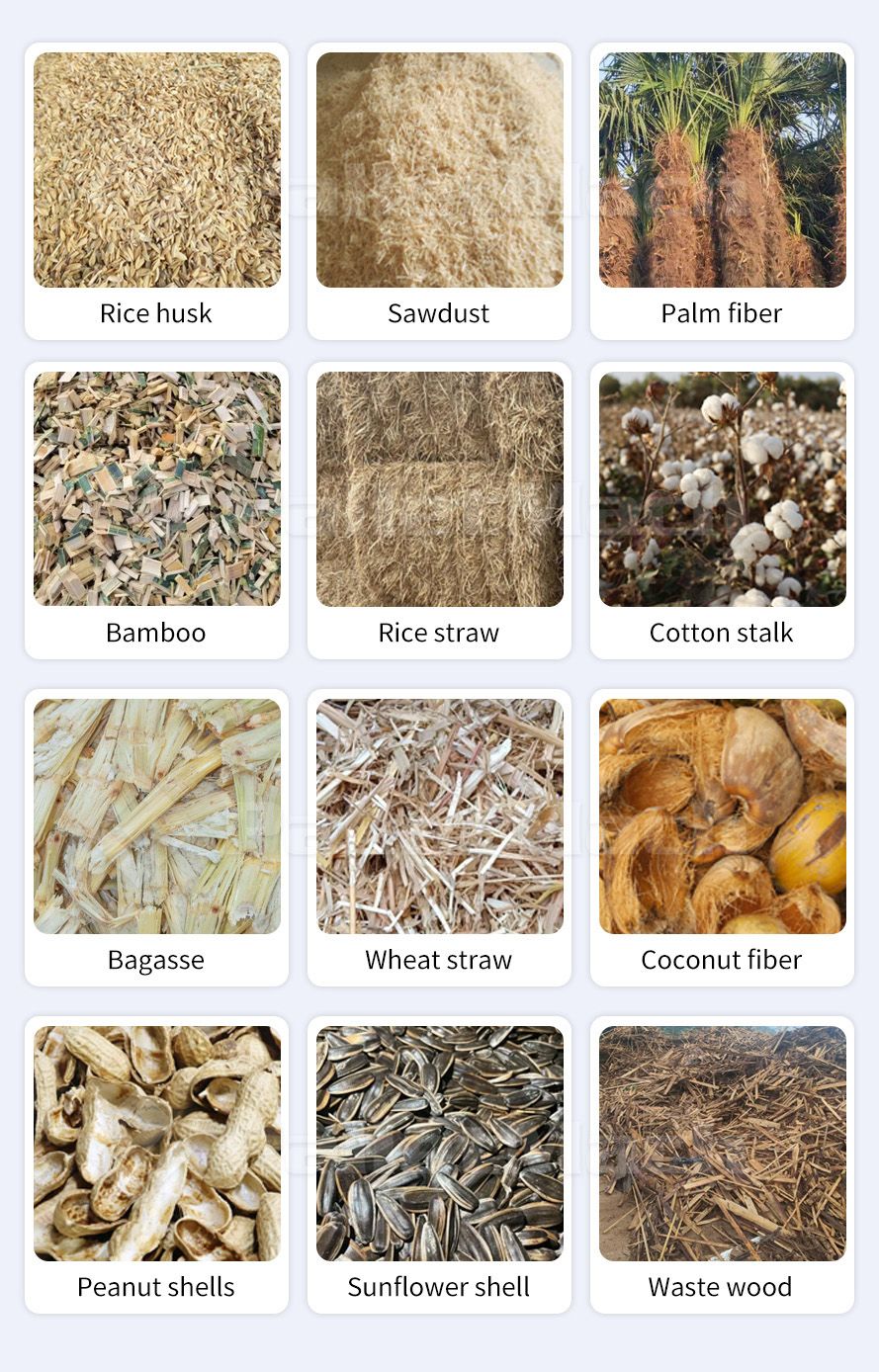

This mature process system can efficiently process a variety of materials, including:

Technical Core

Merely being low-cost is insufficient as an alternative; the key lies in the exceptional performance of the final product. This is the result of the synergistic effect of PalletMach Agricultural Waste Equipment and advanced technology.

1. Intelligent and Efficient Equipment Platform

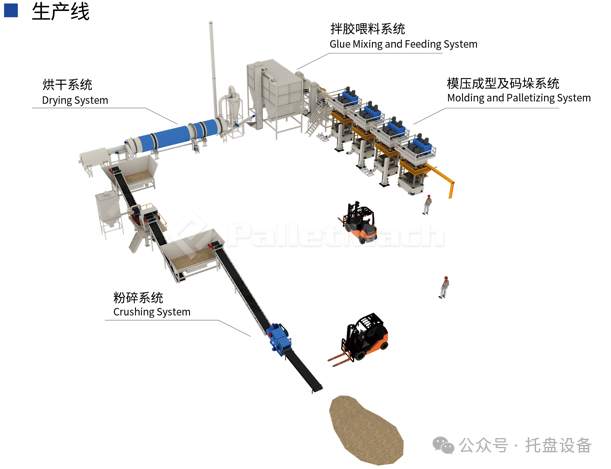

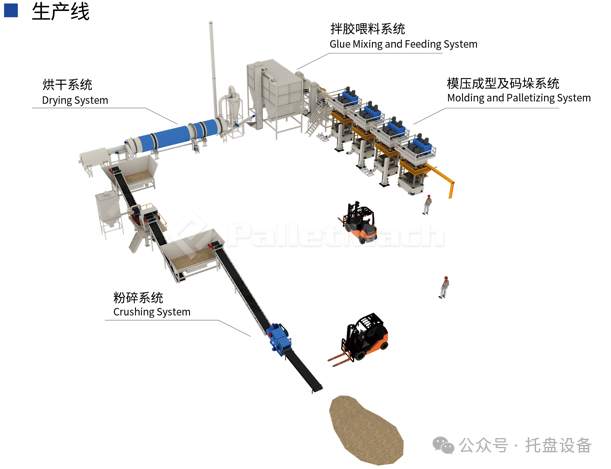

(Automated production line)

(PalletMach wood-pallet-machine)

PalletMach Agricultural Waste Equipment adopts a vertical four-column hydraulic structure, ensuring high precision even during long-term, high-intensity operation. The entire system is centrally controlled by an intelligent PLC, enabling one-touch automated operation from feeding to molding. This high level of intelligence not only guarantees consistent quality for every pallet but also significantly reduces reliance on skilled labor and associated labor costs.

2. Powerful Material Integration Capability

PalletMach Agricultural Waste Equipment, combined with specialized eco-friendly adhesives, creates a robust polyurea cross-linked network between fibers. This tightly integrates originally loose agricultural waste into a unified whole, resulting in pallets whose performance even surpasses that of some wooden pallets:

Outstanding Load Capacity: Dynamic load of 2 tons, static load of 6 tons, meeting heavy-duty freight requirements.

Long-Lasting Durability: Waterproof and pest-resistant, addressing the common issues of mold and cracking in wooden pallets.

(The load-bearing capacity test of the pallet after soaking in water)

(Rice husk molded pallet flame retardant test)

Export Convenience: The high-temperature, high-pressure process naturally meets quarantine standards, exempting it from fumigation and enabling direct access to international markets.

Comprehensive Cost Optimization Beyond Raw Materials

The cost advantages of pallets produced using PalletMach Agricultural Waste Equipment are evident throughout the entire product lifecycle:

Raw Material Revolution

Traditional wooden pallets are constrained by the price of raw timber, resulting in high and uncontrollable cost fluctuations. The core innovation of PalletMach Agricultural Waste Equipment lies in its ability to use widely available agricultural and forestry waste as its primary "feed," completely eliminating reliance on timber.

This mature process system can efficiently process a variety of materials, including:

- Field residues such as straw and rice husks

- Processing by-products like bagasse, peanut shells, and coconut shells

- Wood waste such as scrap wood, sawdust, and branches

Technical Core

Merely being low-cost is insufficient as an alternative; the key lies in the exceptional performance of the final product. This is the result of the synergistic effect of PalletMach Agricultural Waste Equipment and advanced technology.

1. Intelligent and Efficient Equipment Platform

(Automated production line)

(PalletMach wood-pallet-machine)

PalletMach Agricultural Waste Equipment adopts a vertical four-column hydraulic structure, ensuring high precision even during long-term, high-intensity operation. The entire system is centrally controlled by an intelligent PLC, enabling one-touch automated operation from feeding to molding. This high level of intelligence not only guarantees consistent quality for every pallet but also significantly reduces reliance on skilled labor and associated labor costs.

2. Powerful Material Integration Capability

PalletMach Agricultural Waste Equipment, combined with specialized eco-friendly adhesives, creates a robust polyurea cross-linked network between fibers. This tightly integrates originally loose agricultural waste into a unified whole, resulting in pallets whose performance even surpasses that of some wooden pallets:

Outstanding Load Capacity: Dynamic load of 2 tons, static load of 6 tons, meeting heavy-duty freight requirements.

Long-Lasting Durability: Waterproof and pest-resistant, addressing the common issues of mold and cracking in wooden pallets.

(The load-bearing capacity test of the pallet after soaking in water)

(Rice husk molded pallet flame retardant test)

Export Convenience: The high-temperature, high-pressure process naturally meets quarantine standards, exempting it from fumigation and enabling direct access to international markets.

Comprehensive Cost Optimization Beyond Raw Materials

The cost advantages of pallets produced using PalletMach Agricultural Waste Equipment are evident throughout the entire product lifecycle:

- Stable Procurement Costs: Raw materials are widely sourced and stable in price, immune to fluctuations in the timber market.

- Reduced Usage Costs: Longer service life and excellent durability decrease the frequency of pallet replacement and maintenance costs.

- Enhanced Operational Efficiency: The integrally molded, lightweight design ensures stable stacking and more economical transportation. The fumigation-free feature significantly improves cross-border logistics efficiency, saving time and handling fees.

- Added Environmental Value: Using pallets made from agricultural waste is a tangible demonstration of a company's commitment to ESG principles, infusing the brand with a green identity and creating intangible market value.