PalletMach Success Story: Securing Three Orders for Pallet Production Equipment from Ecuadorian Clients.

Pallets, as standardized and efficient tools for logistics, are becoming increasingly important across various industries. PalletMach has always adhered to the three core principles of “Technology, Quality, and Service,” continuously investing in technological R&D and process optimization.

Today, I would like to share a true story of cooperation: Why did an Ecuadorian company choose to partner with PalletMach after 4 years of communication and place 3 repeat orders within a year?

First Contact

In 2020, we received our first email from the client. They not only engaged in pallet production but also had abundant wood waste resources like sawdust. However, they were struggling to find an efficient resource recycling solution. We maintained consistent follow-ups and communication, building trust for future cooperation over the course of four years.

Proactive Follow-Up

In June 2024, the client reached out to us again, requesting to purchase a compressed pallet machine. We quickly responded and fully met their custom requirements:

✅ Adjusted and optimized the existing equipment plan.

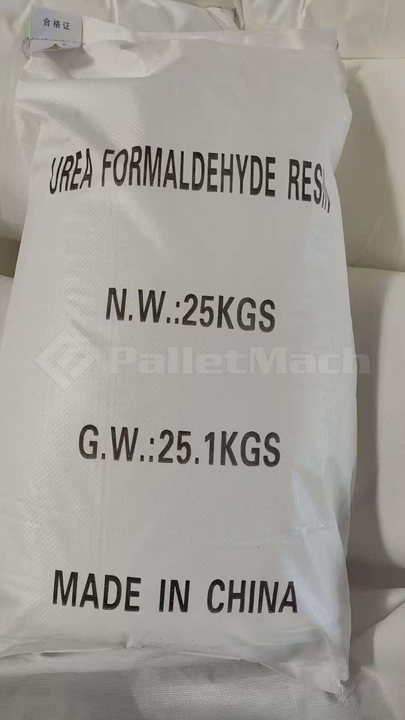

✅ Offered free trial glue powder.

✅ Upgraded the hopper system, adding a spiral conveyor device.

In September, the deal was successfully signed, and we delivered two pallet block machines.

Satisfied with the Trial

In March 2025, after using the glue powder we provided, the client highly praised its bonding effect and cost-performance ratio. They immediately placed an additional order for a small cabinet of glue powder. On April 22, they visited our factory in person to learn more about the entire molded pallet production process.

Repeat Purchase

In May 2025, the client made new procurement requests:

· 12 tons of glue powder;

· One 40-foot container.

During the container loading process, to help the client save on shipping costs, we proactively suggested dismantling thepallet block machines for packing. This allowed us to fit all the glue powder into the container, maximizing space usage and significantly reducing logistics costs.

For large machinery like pallet machines andpallet block machines, shipping costs can account for 10%-30%, or even higher.

The client was deeply touched and, after confirming the order in June, immediately paid the deposit – even before the official contract was sent out!

The Key to Success

It turns out that “a good product is still not enough without exposure.” Product quality is essential, but the service that focuses on the client’s needs is the real key to building cooperation!

From September 2024 to June 2025, the client placed three orders in less than a year, continuing to choose us. This is not just recognition of our product quality but also a deep acknowledgment of our service attitude, response speed, and customer-centric approach. This story represents not just a cooperation record but also the best illustration of our company’s philosophy. It’s the secret to establishing long-term partnerships with customers worldwide.

If you are also looking for an efficient, stable, and worry-free molded pallet orpallet block production solution, feel free to contact us at any time!

Customized Solutions

Additionally, PalletMach can offer tailored solutions for pallet equipment and production lines based on your specific needs. Whether it’s a new project or upgrading an existing production line, we can help companies reduce costs and improve efficiency, advancing green and smart manufacturing.